to help themselves,

to release and realise more of their potential

Dennis Martin Consultants

Contact us and see how we can work together and create a path to the future that you, your people and your business deserve.

- home index page

- The Lubrizol Story

The-Lubrizol-Story:

How to Succeed Against the Odds

SUMMARY OF MAIN PAGE CONTENTS

The-Lubrizol-Story PART ONE is told here and outlines:

* the difficult situation threatening Lubrizol's survival

* the revolutionary and inspiring response that saved the business

* the amazing results achieved from the risk taken

* key learning points are also summarised

The-Lubrizol-Story that follows is largely based on an independent review carried out by David Pollitt, Editor of the 'Training and Management Development and Methods' for Bradford University and some feedback from Samantha Arnold, Head of HR, Lubrizol; Tony Strong, General Manager, Lubrizol and Dennis Martin founder of MDS (Motivational Development Services).

Author: David Pollitt, see above

Category: Case study

Purpose: Highlights the part played by an off-site week-long training and organizational development initiative in helping the Lubrizol chemical company’s UK plant to transform its culture, improve efficiency and, ultimately, secure its future.

Design: Presents information gathered from the plant’s head of human resources, and from the organizational-development consultant involved in the turn-around.

Describes what gave rise to the training “need”, how the training was designed and presented, and the organizational outcomes.

Findings:

Recounts how manufacturing teams have organized themselves into key roles, where each person takes responsibility for a certain area of the job to ensure the process runs smoothly.

Employees now manage their own time, and cover the job without manager approval and without overtime as an incentive.

Manufacturing teams set their own shift patterns.

Finished-product manufacturing time has been reduced by between 10 and 30 per cent because of increased flexibility and greater team working at the plant.

Some £40,000 of savings have been identified through continuous-improvement ideas so far.

Customer-service levels have reached 96 per cent and customer satisfaction stands at 98 per cent.

During the first three months of the new organization, the site was required to take over some manufacturing from the Lubrizol France plant, which had been hit by fire. During this period, Bromborough doubled its volumes while operating with 35 per cent fewer staff, with no loss of business to the organization.

“This greatly enhanced our site profile within the group,” said Samantha Arnold.

The group’s operations vice-president told her: “Without

your plant’s can-do attitude and excellent responsiveness, we would

have had a serious supply gap. Your responsiveness in overcoming all

obstacles was outstanding and very impressive.”

Operating costs were cut significantly.

The-Lubrizol-Story, with its impressive results, is causing the US headquarters to perceive the Bromborough plant positively.

The Bromborough plant has received a Reputation Award from the Chemical Industries Association and two recent ISO audits delivered a ‘best class’ verdict on the site.

In addition, Lubrizol in partnership with MDS, received a UK National Training Award for its unique approach based on complex adaptive systems and whole brain thinking which was described as, ‘revolutionary and inspiring’ by the judges.

There is a PART TWO to this story.

Value:

Provides plenty to interest top management at manufacturing plants faced with the need for radical overhaul in the face of tough competition.

Practical implications:

Demonstrates the value of taking a risk and shutting down operations for a week of training.

At a time of vast uncertainty and immense anxiety, all employees

pulled together and confronted the challenges.

They demonstrated total flexibility and willingness to learn new

skills, embraced collaborative teamwork and, in doing so, created a

more stable future for the plant.

Click the link to go to our Mentoring Definition page.

The-Lubrizol-Story starts when the future looked decidedly difficult for the business and its people.

Fortunately, a new General Manager, Tony Strong was appointed.

The Merseyside, UK, subsidiary of an American chemicals company has secured its future – by closing down for a week-long learning programme developed to provide the tools and techniques to help employees to embrace a new culture.

Based in Bromborough, Wirral, Lubrizol is a fluid-technology company concentrating on high-performance chemicals and services for transportation and industry, and a market leader in speciality additives for lubricants, fuels, coatings, inks, metalworking fluids and personal-care additives.

A subsidiary of the Lubrizol Corporation of Wickliffe, Ohio, it had been scaled down from 270 employees to 70 during the 1990s, and its future was under threat.

“Declines in volumes were not equally matched by reductions in overheads,” said the head of human resources, Samantha Arnold. “The plant was viewed by our corporate head office as a high-cost provider, and its location was seen as a disadvantage compared with other manufacturing plants in Europe.”

With the help of Huddersfield-based consultant Dennis Martin of Motivational Development Services (MDS), Lubrizol developed a strategy to turn the business around by changing the culture and introducing new working practices and behaviours.

Click the link to see more of Dennis's background

Click the link to see how our approach differs

“During 2002 a new site leader was appointed from within,” said Samantha Arnold. “In January 2003 a small steering committee was formed, including Dennis Martin from MDS. Dennis’s successful organizational-development experience was a perfect fit with the radical changes we felt necessary at Lubrizol.”

The steering

committee developed a model to turn the business around using a

change strategy termed “Building the Future at Bromborough”.

This focussed on:

- Bromborough driving its own agenda and thus shaping its own future;

- aligning the organizational structure with business needs;

- significantly reducing operating costs while maintaining current output; and most significantly

- changing the perception of the site to create a future.

“This agenda was a huge challenge for the site as it would require radical changes, including a significant reduction in the workforce, at a time when Bromborough was celebrating its fortieth anniversary,” said Samantha Arnold.

“Furthermore, the timeframe to implement the change was only two months.”

In order to make a break from old traditions, and to introduce new thinking, a decision was made to take all employees off the site for a week.

The planning department communicated well ahead of time the need for reduced production during the re-induction week.

The-Lubrizol-Story learning programme was developed that would provide the tools and techniques to help employees to embrace the new culture.

A set of underlying organizational-design concepts was agreed based on complex adaptive systems and self-management.

In particular, the following key concepts were used to design and deliver the training and learning experiences:

- the removal of “traditional stabilisers” to facilitate self-management and contributions to business success;

- continuous improvement, based on the local-team Kaizen approach;

- whole-brain thinking, including “thinking out of the box”;

- personal responsibility and avoidance of “victim” mentality; and

- developing a learning organization.

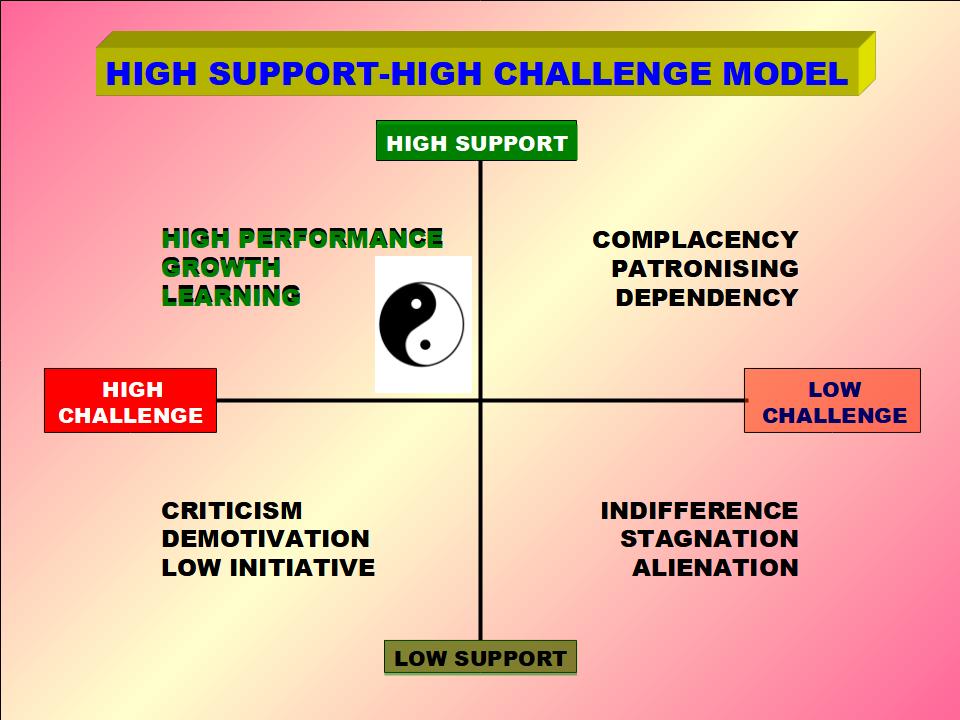

These concepts were refined into a set of culture characteristics that would be used by everyone to ensure high support and high challenge (please see the model below) and as a reference point “to do the right thing”.

The concepts were then used as the basis for learning material during the training week.

This would emphasize:

- the need to be high performing, through continuous improvement and “making it happen”;

- the need to own the business, with everyone being a leader (either formally or informally) and taking personal responsibility;

- the need to be self-managing and team based, and offer mutual support;

- valuing differences, and giving and receiving feedback;

- creating change and seeking innovation; and

- ensuring that everyone felt valued, and valued others.

The objectives of the programme were to:

- learn about the cultural characteristics required to create self-managed and self-financed success;

- provide tools needed to help to manage change;

- begin to work in new teams and break down barriers;

- provide mutual support and guidance and work collectively;

- create action plans to overcome any problems that might arise; and

- share with employees valuable financial information to support an “own the business” culture.

The programme was expected to help employees help themselves and who would then:

- contribute in high-performing teams;

- share in decision making and take personal responsibility;

- demonstrate total flexibility;

- challenge the traditional ways of doing things;

- contribute to savings;

- become multi-tasked and self-managed; and

- own the business.

Click the links to go to our What Does a Mentor Do Page or our What-is-a-mentor? Page

Mornings were dedicated to the development of the new culture, afternoons to practical team building.

One aspect of the programme even included teaching each employee how to juggle, as a way of emphasizing that anyone, irrespective of age or experience, could learn new skills.

Moreover, a social evening was factored into the programme, where employees invited family members to help to share the experience.

Employees were invited to present to those who attended what they believed they had learned so far and what the changes meant to them personally.

Each day started and ended with a review to ensure that learning was taking place and, if necessary, to make adjustments to the format, style or content.

Interaction and mixed-team work were encouraged to help cross-functional team development and encourage diversity of thinking.

In all, 54 manufacturing staff were invited to attend, with those who were unable to do so taking part in a similar three-day programme later.

Those 54 are now doing the work previously covered by almost 100 employees.

One employee commented: “I am sure in my mind that the training and new skills that we learned from Dennis made the transition in changing the organization to the way we work in multi-tasked, self-managed teams possible in a relatively short time.”

Another said: “For the first time ever, the entire workforce was assembled in one room and given the opportunity to understand the business, where it was heading and how each person could make a valued contribution to its ongoing success.”

“Manufacturing teams have organized themselves into key roles, where each person takes responsibility for a certain area of the job to ensure the process runs smoothly,” said Samantha Arnold. “Employees now manage their own time, and cover the job without manager approval and without overtime as an incentive. Manufacturing teams set their own shift patterns.”

During 2004, Bromborough was scheduled to manufacture its highest volume for five years. Finished-product manufacturing time has been reduced by between 10 and 30 per cent because of increased flexibility and greater teamworking at the plant, which has Investor in People status.

Electrical and instrument technicians, for example, are now operating as cross-skilled manufacturing technicians. Manufacturing technicians are performing tasks in warehouse and shipping operations while maintaining their “main” roles.

Customer-service levels have reached 96 per cent and customer satisfaction stands at 98 per cent.

Two new change facilitators have been appointed, and the teams are being mentored by them to help to make improvements and work through issues and ideas.

A paperless 360-degree feedback process has been introduced as a way of improving communication and personal performance.

Some £40,000 of savings have been identified through continuous-improvement ideas so far.

Bromborough’s internal target in 2003 was to convert 30 per cent of new business contacts into actual business. It exceeded this target by 11 per cent and increased the 2004 target to 50 per cent.

“We took a risk and effectively shut down operations for a week of training,” said Samantha Arnold. “At a time of vast uncertainty and immense anxiety, all employees pulled together and confronted the challenges.

They demonstrated total flexibility and willingness to learn new skills, embraced collaborative teamwork and, in doing so, created a more stable future for our plant.”

Click a link to go to our Small Business Mentoring and / or

Business mentoring pages

The-Lubrizol-Story Points for thought

When cost-cutting exercises are introduced the training budget is

often the first area to be under the spotlight for rationalization.

Lubrizol did the opposite, believing that to bring about

successful change, time and resources needed to be invested up front

to help to embed change and make it a success.

At a time when business was declining and corporate perception of

the Bromborough plant was poor, Lubrizol took a risk and

effectively shut down operations for one week and involved the

entire workforce in helping the business to be successful in the

future. This was a radical and high-risk approach.

The returns realized on the training investments made exceeded

everyone’s expectations. The response in picking up

manufacturing in a crisis when the French fire occurred was

recognized as outstanding by Lubrizol Corporation.

The decision to involve all employees and engage their partners in

the process of change meant that employees had support from the

family as well as within the work environment. This was a

creative and radical way to embed the changes both personally and

within the workplace.

At a time of vast uncertainty and immense anxiety, all employees pulled together and confronted the challenges that faced them. Employees demonstrated total flexibility and willingness to learn new skills, embraced collaborative teamwork, rose to the challenge and, in doing so, created a more stable future for the plant.

go back to our HOME PAGE go to our PRIVACY POLICY

So, PAGE SUMMARY

The-Lubrizol-Story PART ONE is told here and outlines:

* the difficult situation threatening Lubrizol's survival

* the revolutionary and inspiring response that saved the business

* the amazing results achieved from the risk taken

* key learning points are also summarised

* proof that our Small-Business-Mentor approach works

We've covered a lot of ground on this page and I just want to THANK YOU for visiting my web site and reading this page. Your attention is much appreciated.

I hope you found the page as worthwhile and interesting reading it as I did writing it.

Kindest regards,

Dennis